THE K-FLEX TITAN. THIS CHANGES EVERYTHING

The K-FLEX TITAN coated pipe insulation is a whole new level of durable. It’s tear resistant. UV resistant. You can push it, pull it, even yank it through walls. That means quicker installations and more jobs done in a day.

TRY IT NOW FOR FREE!

THE COMPETITION’S PIPE INSULATION IS STARTING TO SWEAT

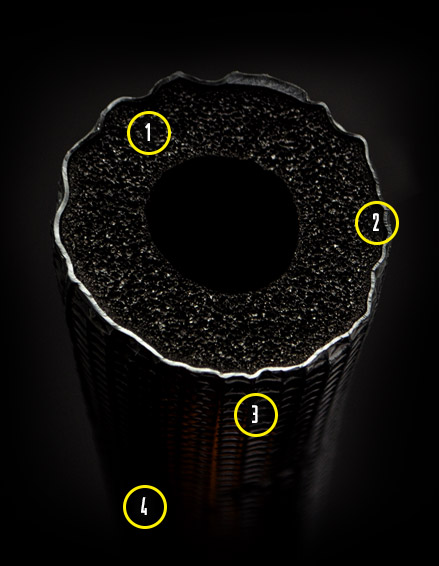

1. ULTIMATE INSULATION

2. DURABLE PROTECTION

3. CODE COMPLIANCE

4. 1-STEP INSTALL

Want to test it yourself?

TECHNICAL SPECIFICATION

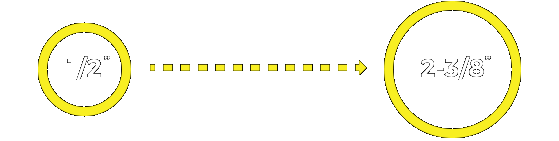

AVAILABLE ID SIZES

Available Wall Thickness

Available Lengths

HAVE ANY QUESTIONS?

FAQ’S

Insul-Tube (NBR/PVC elastomeric) insulation with a patent-pending, factory-applied, flexible and durable polymeric jacketing.

Available in 6’ lengths (non-slit or pre-slit), small coils (50’-100’), or as a pre-insulated copper line set (line sets available from Mueller Industries or Linesets Inc.). The size offering is ¼” to 2-1/8” ID x ½” to 1-1/2” wall.

Properly sized insulation tubing can be slid over piping (tubing should be pushed, not pulled). All seams, butt joints, termination points and open ends should be sealed with 320 or 620 contact adhesive, making sure both surfaces to be joined are coated. Vapor stops should be installed as needed. K-Flex Titan may be slit longitudinally for retrofit applications. On straight runs, seams should be facing down to reduce weight/pressure on the seam. For additional protection on the longitudinal seam, apply Titan Tape over entire length of the seam.

Yes, a one component acrylic rubber paint formulated for use on rubber roofing membranes is an acceptable coating for K-Flex Titan. Products such as Heng’s Rubber Roof Coating manufactured by Heng’s Industries or similar can be used. Similar products may be found at roofing specialty distributors or at RV service and parts stores. K-Flex Titan must be clean and dry prior to application. Apply 2 coats of paint by brush or roller. Dry to touch in 4 hours, cures in 8 hours depending upon conditions. Paint is white, but can be tinted. Contact the manufacturer for acceptable tinting methods. Paints and coatings require periodic maintenance, and life expectancy will vary based on exposure conditions.

Yes, the product has a continuous temperature resistance to 220°F and can withstand spikes up to 250°F (qualified by ASTM C411 testing) meeting the requirements of VRF system specifications. The suitability is further proven by more than 50 million linear feet installed on VRF systems over the past 3 years.

Yes, K-Flex meets all requirements of the 2012, 2015, 2018 and 2021 IECC code for residential and commercial facilities. The product also meets the requirements of the current California Title 24 energy code.

You can download a technical spec sheet here: https://fd.ax/s4

Visit the approved distributor list on kflextitan.com or contact a K-Flex sales representative.

FIND A DISTRIBUTOR